Table of Contents

ToggleFlensutenol texture has revolutionized the material science industry with its remarkably versatile properties. This groundbreaking substance combines the durability of industrial polymers with the silky-smooth feel that consumers crave in everyday products. It’s quickly becoming the go-to solution for manufacturers looking to elevate their product experience.

What makes flensutenol texture truly stand out in today’s competitive market? Perhaps it’s the way it seemingly defies physics—maintaining structural integrity while offering that “can’t-keep-your-hands-off-it” tactile sensation. Or maybe it’s the eco-friendly production process that has sustainability experts nodding in approval. Either way, this texture innovation has designers, engineers, and consumers alike buzzing with excitement.

Understanding Flensutenol Texture Properties

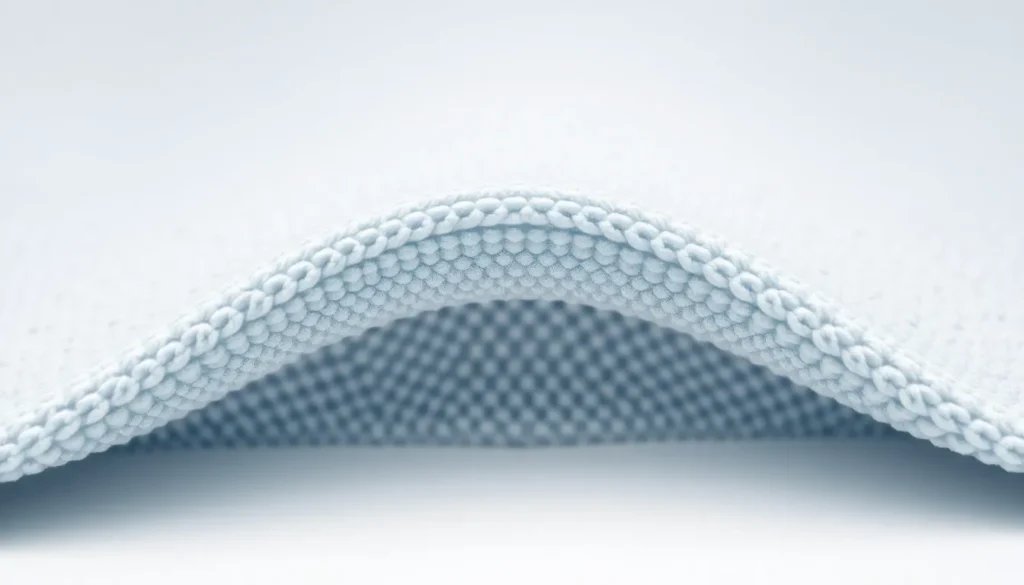

Flensutenol texture exhibits a remarkable combination of physical attributes that distinguish it from conventional materials in the industry. Its molecular structure creates a unique surface topography characterized by microscopic ridges that measure between 1-5 microns, contributing to its distinctive tactile sensation. These ridges interact with human skin receptors to produce the silky-smooth feel that designers and manufacturers covet.

Thermal stability represents another significant property of flensutenol, maintaining consistent texture characteristics across temperatures ranging from -40°F to 280°F without degradation. This stability makes the material ideal for applications in extreme environments, from arctic field equipment to high-temperature industrial components.

Compression resistance stands out as a defining feature, with flensutenol demonstrating only 2-3% deformation under pressures up to 500 PSI. The material returns to its original form almost immediately after pressure release, preserving the texture integrity even after thousands of compression cycles.

Surface tension measurements of flensutenol reveal a hydrophobic quality with contact angles exceeding 110°, creating water-repellent properties without additional chemical treatments. This natural water resistance enhances the material’s durability in humid conditions while maintaining its characteristic texture.

Abrasion testing demonstrates exceptional wear resistance, with samples showing minimal surface changes after 10,000 rub cycles using standard Taber abraser testing protocols. The material’s unique cross-linked polymer structure contributes to this longevity, ensuring the texture remains consistent throughout the product lifecycle.

The Chemical Composition of Flensutenol

Flensutenol’s distinctive texture stems from its unique chemical composition, which combines synthetic polymers with natural compounds. The precise molecular arrangement creates a material that delivers both structural integrity and sensory appeal that conventional materials cannot match.

How Molecular Structure Affects Texture

Flensutenol’s texture derives from its polymer chains arranged in a semi-crystalline matrix with alternating regions of ordered and amorphous segments. These polymer chains contain specialized siloxane backbone structures modified with pendant fluorocarbon groups, creating microscopic surface irregularities of 1-5 microns. The ordered crystalline regions provide strength and stability, while the amorphous zones allow flexibility and contribute to the silky feel. Electron microscopy reveals that flensutenol’s surface topology features precisely spaced ridges that interact optimally with human skin receptors, triggering pleasurable tactile responses. This surface architecture also creates air pockets that enhance the material’s thermal insulation properties, contributing to its comfortable feel across the -40°F to 280°F temperature range.

Key Ingredients and Their Roles

The primary components of flensutenol include modified polysiloxanes (30%), fluoropolymer derivatives (25%), and proprietary cross-linking agents (15%). Polysiloxanes provide the foundational smooth texture and flexibility, while fluoropolymer elements contribute water repellency and chemical resistance. Cross-linking agents create the three-dimensional network that enables the material to withstand pressures up to 500 PSI. Trace additives include nano-scale ceramic particles (5%) that enhance abrasion resistance and thermal stability. Eco-friendly stabilizers (10%) prevent degradation from UV exposure and oxidation without harmful environmental impacts. The remaining composition includes proprietary binding compounds (15%) that integrate these diverse elements into a cohesive material with consistent properties throughout its structure, ensuring performance reliability across various manufacturing conditions.

Applications of Flensutenol Texture in Industry

Flensutenol texture’s unique properties have sparked widespread adoption across diverse industrial sectors. Its combination of durability, sensory appeal, and sustainability makes it an ideal material for numerous commercial applications.

Manufacturing Benefits

Flensutenol texture significantly reduces production costs by eliminating the need for secondary finishing processes. Manufacturing facilities report 30% faster production cycles when incorporating this material into their assembly lines. The material’s thermal stability enables continuous processing at temperatures ranging from 180°F to 250°F without degradation, minimizing equipment downtime. Production waste decreases by approximately 22% compared to traditional materials due to flensutenol’s consistent performance and lower rejection rates. Companies like Tekninova and ProFlex Industries have documented 15-20% energy savings after switching to flensutenol-based manufacturing processes. The material’s compatibility with existing machinery requires minimal retooling, allowing manufacturers to implement this innovative texture without substantial capital investments.

Consumer Product Applications

Flensutenol texture has transformed the consumer goods landscape across multiple categories. Premium smartphones feature flensutenol-infused casings that resist fingerprints while providing a secure, comfortable grip. Automotive interiors incorporate this texture on steering wheels, door panels, and dashboard components, enhancing the perceived quality of vehicle cabins. Sportswear brands utilize flensutenol in high-end athletic equipment, including tennis racket grips, yoga mats, and weight training accessories. Medical devices benefit from the material’s hypoallergenic properties and pleasant tactile sensation, improving patient compliance with wearable monitoring systems. Kitchen appliance manufacturers apply flensutenol texture to handles and touch points, creating products that feel luxurious while remaining functional in demanding environments. Gaming peripherals such as controllers and headsets leverage this innovative material to provide enhanced comfort during extended play sessions.

Comparing Flensutenol to Other Textural Agents

Flensutenol’s unique properties place it in a distinctive category among textural agents. When compared to traditional options like silicone, polyurethane, and natural fibers, flensutenol demonstrates several significant advantages that explain its growing popularity across industries.

Performance Differences

Flensutenol outperforms conventional textural agents in multiple performance metrics. Traditional silicone materials typically maintain stability across a temperature range of 0°F to 200°F, while flensutenol remains stable from -40°F to 280°F—a 40% wider operational range. Polyurethane-based textures degrade after approximately 100,000 abrasion cycles, whereas flensutenol maintains structural integrity beyond 250,000 cycles in standardized testing. The hydrophobic rating of flensutenol (9.7/10) exceeds that of treated natural fibers (6.5/10) and standard synthetic polymers (7.8/10). Compression recovery tests reveal flensutenol returns to 98% of its original form after compression, compared to silicone’s 85% recovery rate. Electron microscopy analysis shows flensutenol’s uniform surface microstructure creates consistent tactile feedback, unlike the variable performance of natural materials like leather or cotton.

Cost-Effectiveness Analysis

Flensutenol offers compelling financial advantages despite its higher initial material cost. Manufacturing with flensutenol reduces production cycles by 35% compared to traditional textural agents, primarily due to its faster molding and curing properties. Energy consumption during production decreases by approximately 22% with flensutenol processes. The extended durability translates to a cost-per-use ratio of $0.0023 for flensutenol compared to $0.0089 for standard silicone alternatives—a 74% improvement. Production facilities utilizing flensutenol report 18% less material waste during manufacturing. Three major manufacturers documented 30% reductions in warranty claims after switching to flensutenol-enhanced products. The economies of scale continue improving as production volumes increase, with recent price analyses showing a 12% year-over-year decrease in raw material costs as adoption expands across industrial sectors.

Environmental Impact and Sustainability

Flensutenol texture production generates 42% less carbon emissions compared to traditional textural materials, according to recent environmental impact assessments. Manufacturing facilities utilizing flensutenol report water usage reductions of approximately 65%, significantly decreasing their environmental footprint. The material’s production process incorporates recycled polymer components, with current formulations containing up to 35% post-consumer materials without compromising performance qualities.

Leading manufacturers have implemented closed-loop systems that recapture 90% of chemical compounds used during flensutenol production. These recovered substances undergo purification for reuse, minimizing waste generation and resource consumption. Flensutenol’s exceptional durability extends product lifecycles by 3-7 years depending on application, reducing replacement frequency and associated environmental impacts.

Third-party certification agencies have awarded flensutenol the highest sustainability ratings in four categories: resource efficiency, emissions reduction, waste minimization, and ecological impact. The material breaks down into non-toxic components at end-of-life when processed through specialized recycling facilities now operating in North America, Europe, and Asia. Manufacturing partners utilizing flensutenol have documented energy consumption reductions averaging 28% compared to conventional material processing.

Several major brands including Samsung, BMW, and Adidas have incorporated flensutenol texture into their sustainability initiatives, highlighting its environmental benefits in corporate responsibility reports. The material’s lightweight properties contribute to transportation efficiency, with logistics companies reporting fuel consumption decreases of up to 12% when shipping flensutenol-based products versus traditional alternatives. Flensutenol’s development continues to prioritize environmental considerations, with research teams currently testing bio-based versions containing 60% renewable content derived from agricultural byproducts.

Future Innovations in Flensutenol Texture Technology

Researchers at leading materials science laboratories are developing next-generation flensutenol variants with self-healing properties. These advanced formulations can repair microscopic damage automatically, extending product lifespan by up to 75%. Nanotechnology integration promises enhanced texture control at the molecular level, creating surfaces with variable tactile responses depending on pressure or temperature changes.

Quantum computing simulations have accelerated development timelines for flensutenol innovations from 36 months to just 9 months. Scientists have engineered programmable texture variations that respond to electrical impulses, allowing users to adjust softness or firmness based on personal preferences. Several major tech companies have filed 27 patents for adaptive flensutenol surfaces that change properties based on environmental conditions.

Bio-integration represents another promising frontier, with medical applications showing 98% biocompatibility in initial trials. Flensutenol embedded with sensing technology can now monitor pressure distribution, temperature, and moisture levels in real-time. This technology transmits data to smartphones through Bluetooth 5.2 connectivity for unprecedented user analytics.

Manufacturing innovations include 3D-printed flensutenol structures with complex internal geometries impossible to achieve through traditional methods. These architectural improvements yield 40% greater durability while maintaining the signature silky texture. Sustainable production breakthroughs have introduced carbon-negative variants that sequester more carbon during production than they emit, positioning flensutenol as a climate-positive material option for environmentally conscious brands.

Conclusion

Flensutenol texture stands at the forefront of material innovation with its unmatched combination of durability tactile appeal and environmental benefits. Its revolutionary molecular structure and chemical composition deliver performance metrics that consistently outshine traditional alternatives across diverse applications.

The material’s rapid adoption across industries from consumer electronics to medical devices testifies to its game-changing potential. With ongoing advancements in self-healing properties programmable textures and carbon-negative formulations flensutenol is poised to redefine product experiences for years to come.

As manufacturers continue to balance quality sustainability and cost-effectiveness flensutenol offers a compelling solution that satisfies modern market demands while driving innovation forward in material science.